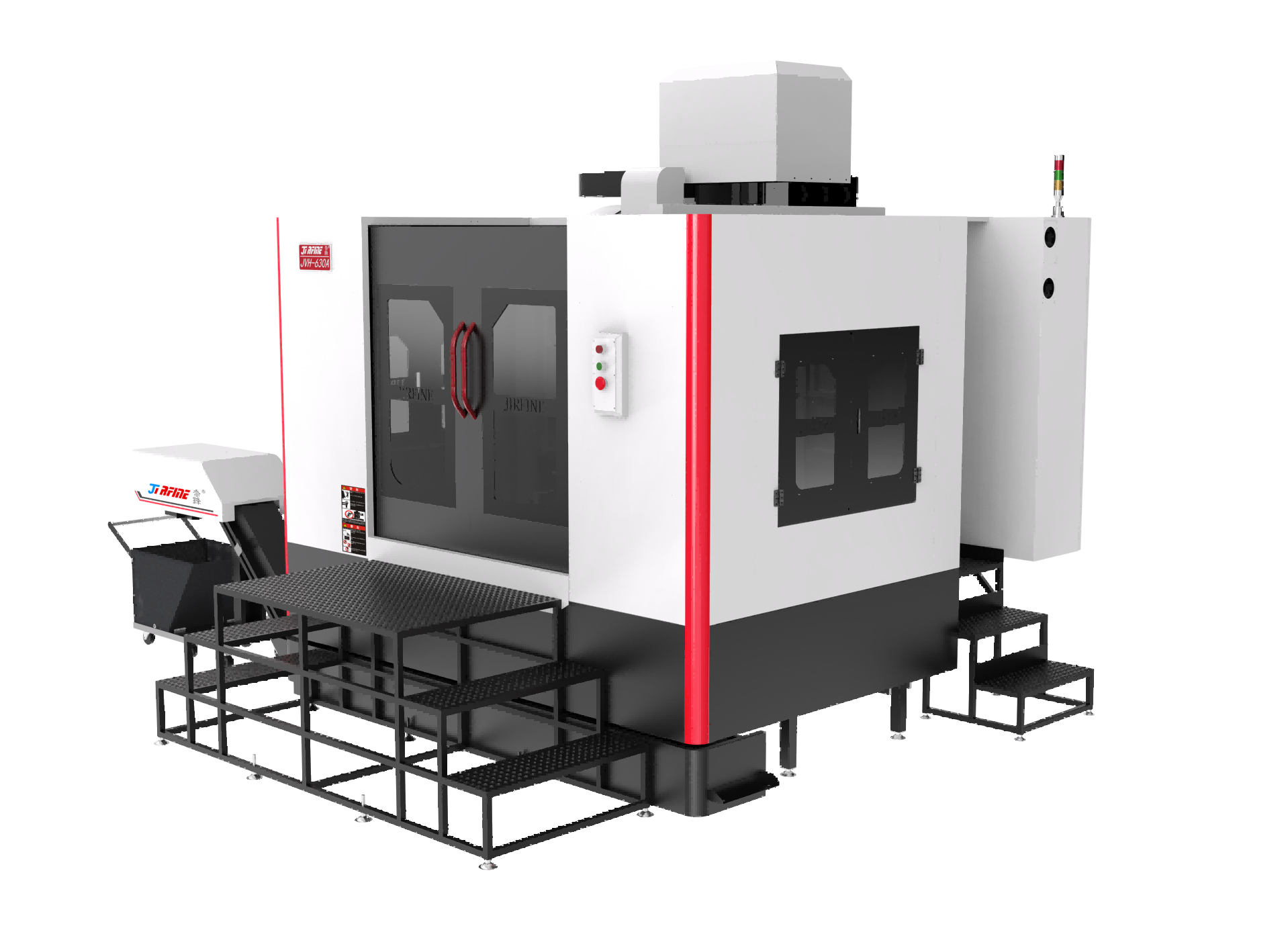

Feature

01

The casting adopts an integrated box design with dual ribbing arm structure to provide optimal support and dynamic stability

02

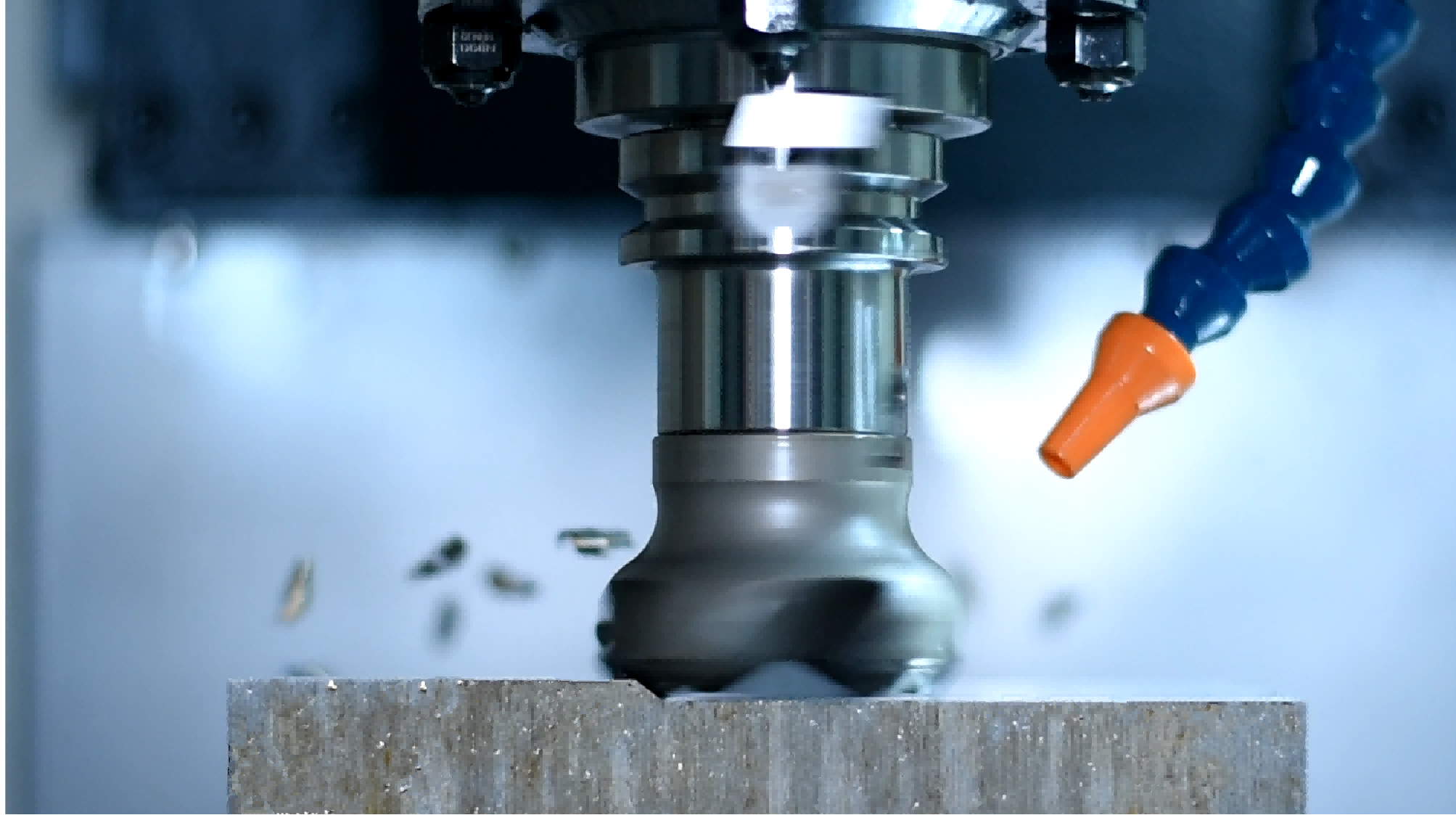

Three-axis adopts ball linear slide rail with low friction coefficient,and the span of linear slide rail has golden ration distribution,with accurate and smooth cutting feed

03

The ball screws are driven by the motor through direct type,and the screws are pre-pulled with precision angular contact ball bearing to provide the optimal feed rigidity and precision

Specifications

Item

Project

Unit

Specifications

Working table

Size of working table

mm

630x630

Max .workpiece size(diameter x height)

mm

φ600x750

Max. load

kg

1200

Indexing angle

#

0.001°

Travel

Travel of X-axis (left and right)

mm

1300

Travel of Y-axis (up and down)

mm

950

Travel of Z-axis (front and back)

mm

710

Max. rotation diameter of workpiece

mm

1300

Distance between spindle center and the working table center

mm

135~845 (Belt drive-standard configuration)

Distance between spindle center and the working table surface

mm

-70~880

Belt type spindle-optional

mm

1380

Spindle

Spindle taper

#

BT-50

Diameter of spindle bearing

#

NN3020 x 1; φ100mm x 2; NN3018 x 1

Spindle speed

rpm

4500(6000OPT)

Rapid displacement

Three-axis cutting feed rate

m/min

1~10000

Three-axis rail

#

Roller drive linear slide rail

Three-axis rapid motion rate

m/min

20

Tool storage bin

Tool capacity

pcs

30

Applicable tools

#

Move the tool arm across

Max. adjacent tool diameter x length

mm

φ105x300

Max. tool weight

kg

18

Tool holder specification

#

BT-50

Driving motor

Spindle motor

W

15/18.5 Continuous / 15min fixed frame (belt spindle)

Three-axis servo motor

kW

3.0(Y axis with brake)

Turntable servo motor

kW

3

Cutting fluid motor

W

1000

Conveyor motor

HP

1/4

General specification

Overall dimension(L x W x H)

mm

5000x4300x3650