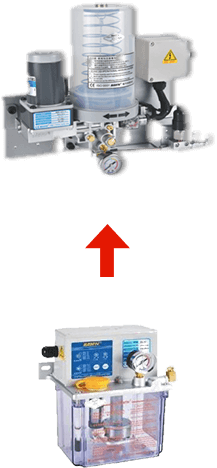

After upgrading the grease lubrication system, each machine tool of Jirfine saves annually 176 liters of chemical oil

-

01Grease Lubrication System Upgrade

The standard lubrication system of the whole series of vertical and drilling machines is upgraded from thin oil lubrication to grease lubrication.

- · Less grease consumption, more environmentally friendly

- · Long maintenance intervals for greater conve nience

- · Quickly change the oil pack, more convenient

- · The cutting fluid is less oily and more durable

-

02Adapt to different working conditions, Comes with two types of grease

-

Normal temperature type ALA-07-00

suitable for southern customers (above -5℃ )

-

Low temperature type ALB-07-00

suitable for northern customers (above -20℃ )

-