Feature

01

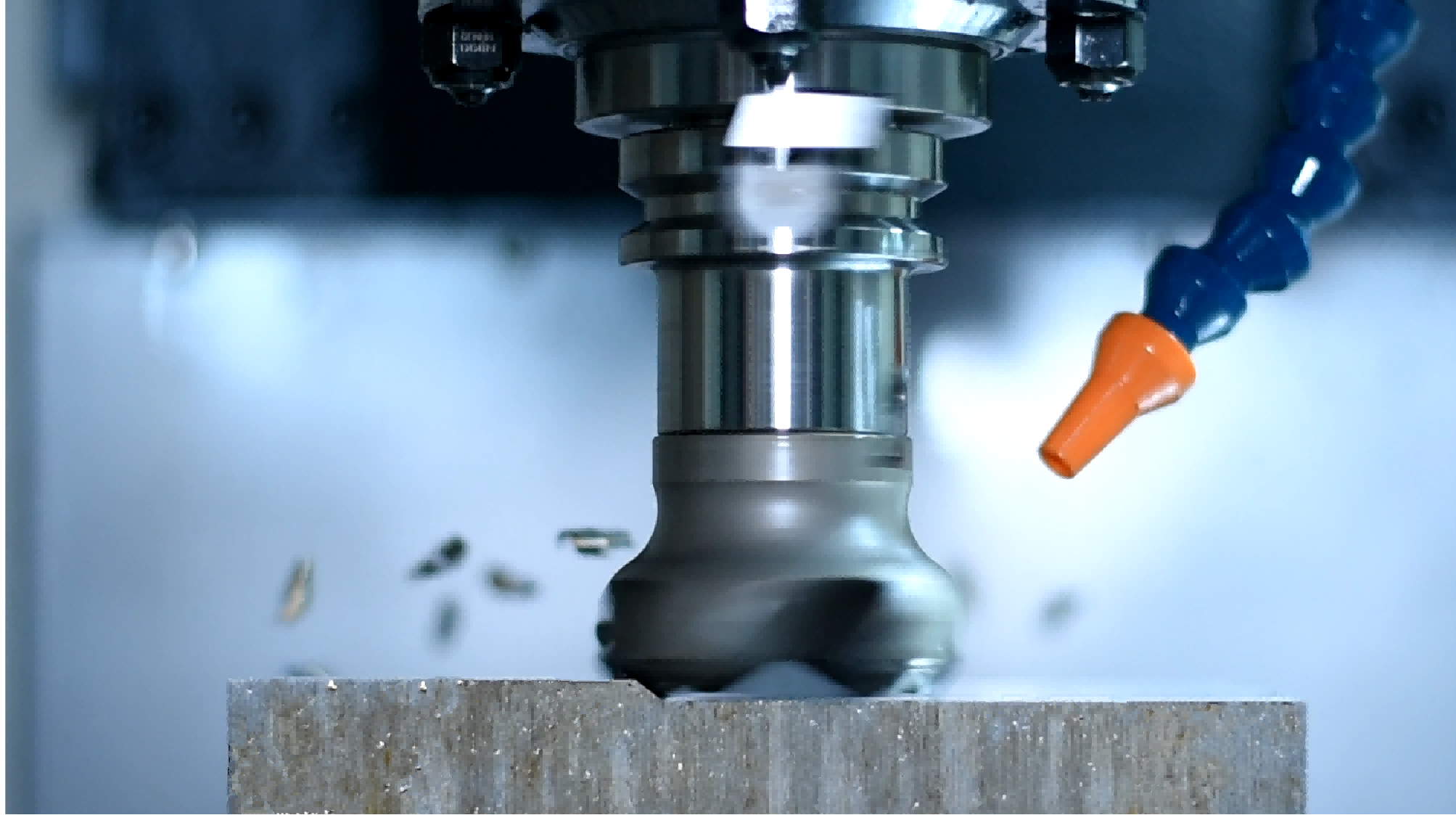

The ultra travel of three-axis is able to cover 95% of the 5G product processing market.

02

The three-axis rapid displacement is 36m/min, and the standard 12000rpm direct-coupled spindle

provides strong support for high-speed and efficient machining

03

The standard automatic timing and quantitative grease lubrication system reduces the

pollution of thin oil to the cutting fluid and improves the service life of the cutting fluid.

Specifications

| V-1270 | Project | Unit | Specifications |

|---|---|---|---|

| Travel | X axis travel | mm | 1200 |

| Y axis travel | mm | 700 | |

| Z axis travel | mm | 600 | |

| Distance from spindle nose to worktable | mm | 100-700 | |

| Distance from spindle center to Z-axis shield | mm | 715 | |

| Workbench | Workbench size | mm | 1320x650 |

| T-slot(size x slot no. x space) | mm | 18x5x100 | |

| Maximum load of workbench | kg | 600 | |

| Spindle | Speed | rpm | 12000 |

| Spindle taper | # | BBT40 | |

| Transfer method | # | Direct drive | |

| Feed | Three-axis cutting feed | mm/min | 1-10000 |

| Three-axis rapid feed | m/min | 36x36x36 | |

| Precision | Positioning precision (X/Y/Z) | mm | 0.008/0.007/0.006 |

| Repeatability (X/Y/Z) | mm | 0.005/0.004/0.004 | |

| Tool changing system | Number of tools | pcs | 24 |

| Max tool weight | kg | 7 | |

| Max tool length | mm | 300 | |

| Max tool diameter(Full tool/adjacent empty tool) | mm | 80/150 | |

| Tool magazine form | # | Disc | |

| CNC system | Control system | # | FANUC 0I-MF plus(5) (Mitsubishi M80A/M80B) |

| Spindle motor power | kw | 11/18.5 | |

| Three-axis motor power | kw | 3.0/3.0/3.0 | |

| Others | Required air pressure | kgf/cm³ | ≥6 |

| Electricity demand | KVA | 25 | |

| Dimensions(LxWxH) | mm | 3280x2660x2910 |