Feature

01

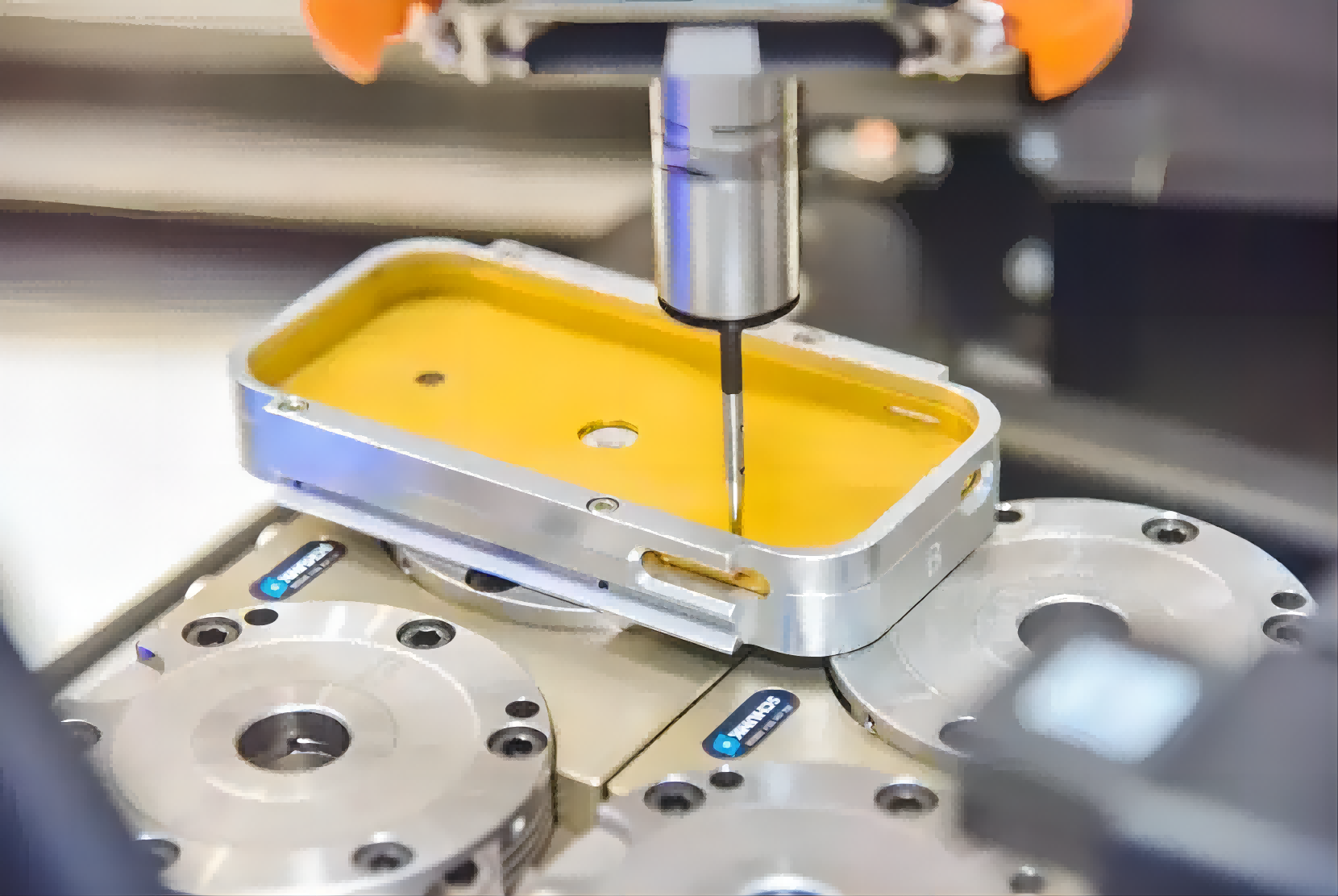

High speed servo tool change system, with a tool to tool change time of 1.4

seconds, greatly improving tool change efficiency

02

The box structure is designed with W reinforcement and beige reinforcement inside,

greatly improving the rigidity of the body

03

Integrated molding technology is adopted for the machine body, providing higher

processing stability and extending the service life of the machine tool

Specifications

Item

Project

Unit

Specifications

Travel

X axis travel

mm

700

Y axis travel

mm

400

Z axis travel

mm

350

Distance from spindle nose to worktable

mm

150-450

Distance from spindle center to column

mm

411

Workbench

Workbench size

mm

850x400

T-slot(sizexslot no.xspace)

mm

14x3x125

Maximum load of workbench

kg

350

Spindle

Speed

rpm

20000

Spindle taper

#

BT30

Transfer method

#

Direct drive

Feed

Three-axis cutting feed

mm/min

1-10000

Three-axis rapid feed

m/min

48/48/48

Precision

Positioning precision

mm

0.007/0.005/0.005

Repeatability

mm

0.004/0.003/0.003

Tool changing system

Number of tools

pcs

21

Max tool weight

kg

3

Max tool length

mm

250

Tool diameter (full tool/neighbor empty tool)

mm

100/140

Tool magazine form

#

Jaw type (servo)

CNC system

Control system

#

FANUC 0I-MF

Spindle motor power

kw

3.7/9

Three-axis motor power

kw

2.5/2.5/3

Others

Required air pressure

kgf/cm3

≥6

Electricity demand

KVA

15

Net weight

kg

/

Dimensions(LxWxH)

mm

1890x2573x2442