Feature

01

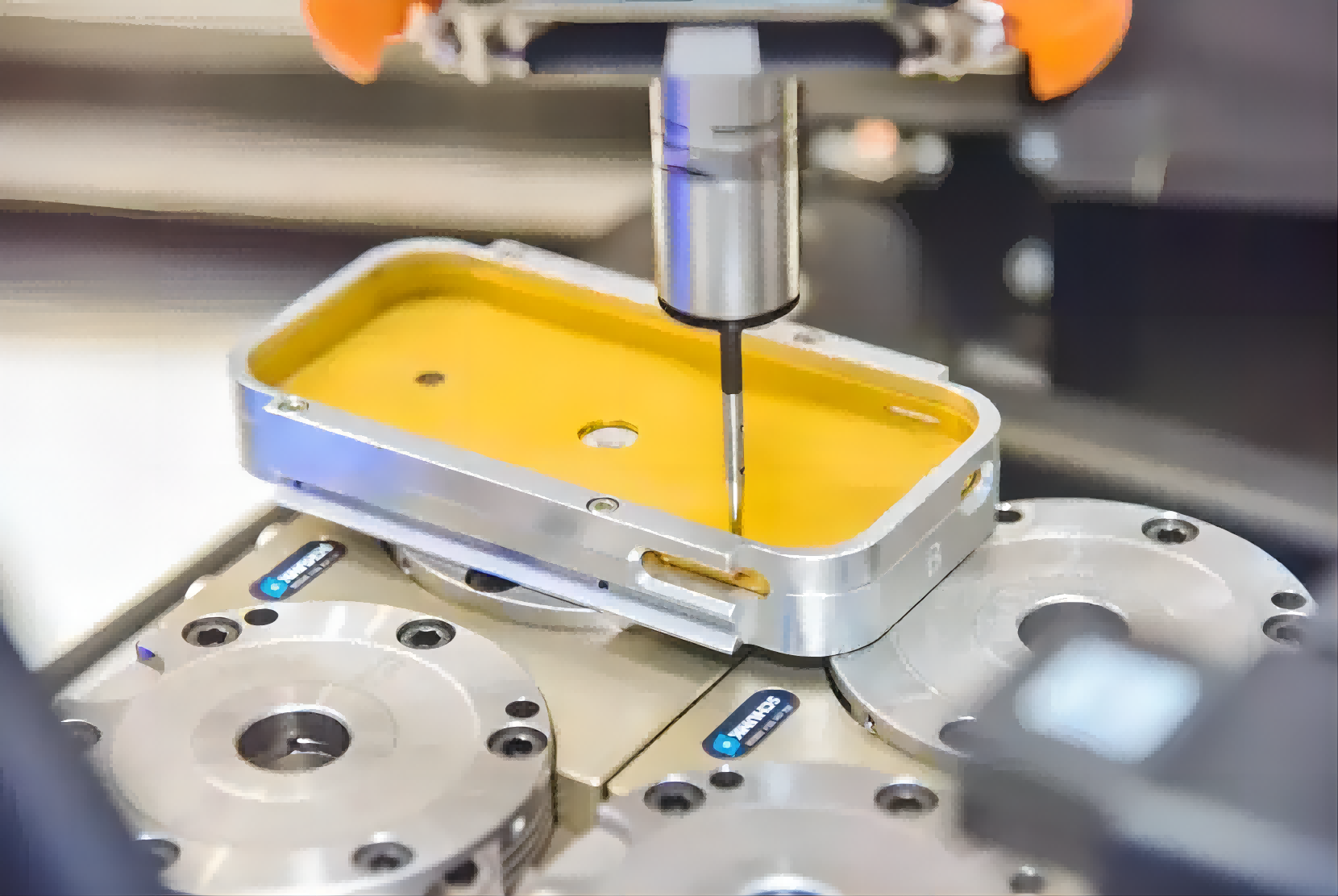

Golden ratio span design, high-speed and high-precision machining is more guaranteed

02

Spindle direct drive design, directly output speed from the motor axis to obtain high-quality tapping effect

03

Super large X/Y-axis travel breaks through the dilemma that traditional drilling and tapping machines cannot process large workpieces

Specifications

| Item | Project | Unit | Specifications |

|---|---|---|---|

| Travel | X axis travel | mm | 1000 |

| Y axis travel | mm | 500 | |

| Z axis travel | mm | 300 | |

| Distance from spindle nose to worktable | mm | 180-480 | |

| Distance from spindle center to column | mm | 550 | |

| Workbench | Workbench size | mm | 1100x500 |

| T-slot(sizexslot no.xspace) | mm | 14x5x80 | |

| Maximum load of workbench | kg | 400 | |

| Spindle | Speed | rpm | 12000 |

| Spindle taper | # | BT30 | |

| Transfer method | # | Direct drive | |

| Feed | Three-axis cutting feed | mm/min | 1-10000 |

| Three-axis rapid feed | m/min | 48/48/48 | |

| Precision | Positioning precision | mm | 0.008/0.005/0.005 |

| Repeatability | mm | 0.005/0.003/0.003 | |

| Tool changing system | Number of tools | pcs | 21 |

| Max tool weight | kg | 3 | |

| Max tool length | mm | 250 | |

| Tool diameter (full tool/neighbor empty tool) | mm | 100/140 | |

| Tool magazine form | # | Jaw type (servo) | |

| CNC system | Control system | # | FANUC 0I-MF |

| Spindle motor power | kw | 3.7/13 | |

| Three-axis motor power | kw | 2.7/2.7/3.0 | |

| Others | Required air pressure | kgf/cm3 | 6 |

| Electricity demand | KVA | 20 | |

| Net weight | kg | / | |

| Dimensions(LxWxH) | mm | 2460x2860x2420 |