Feature

01

The machine body is made of high-grade castings, with design of box structure and

multi stiffeners to improve rigidity

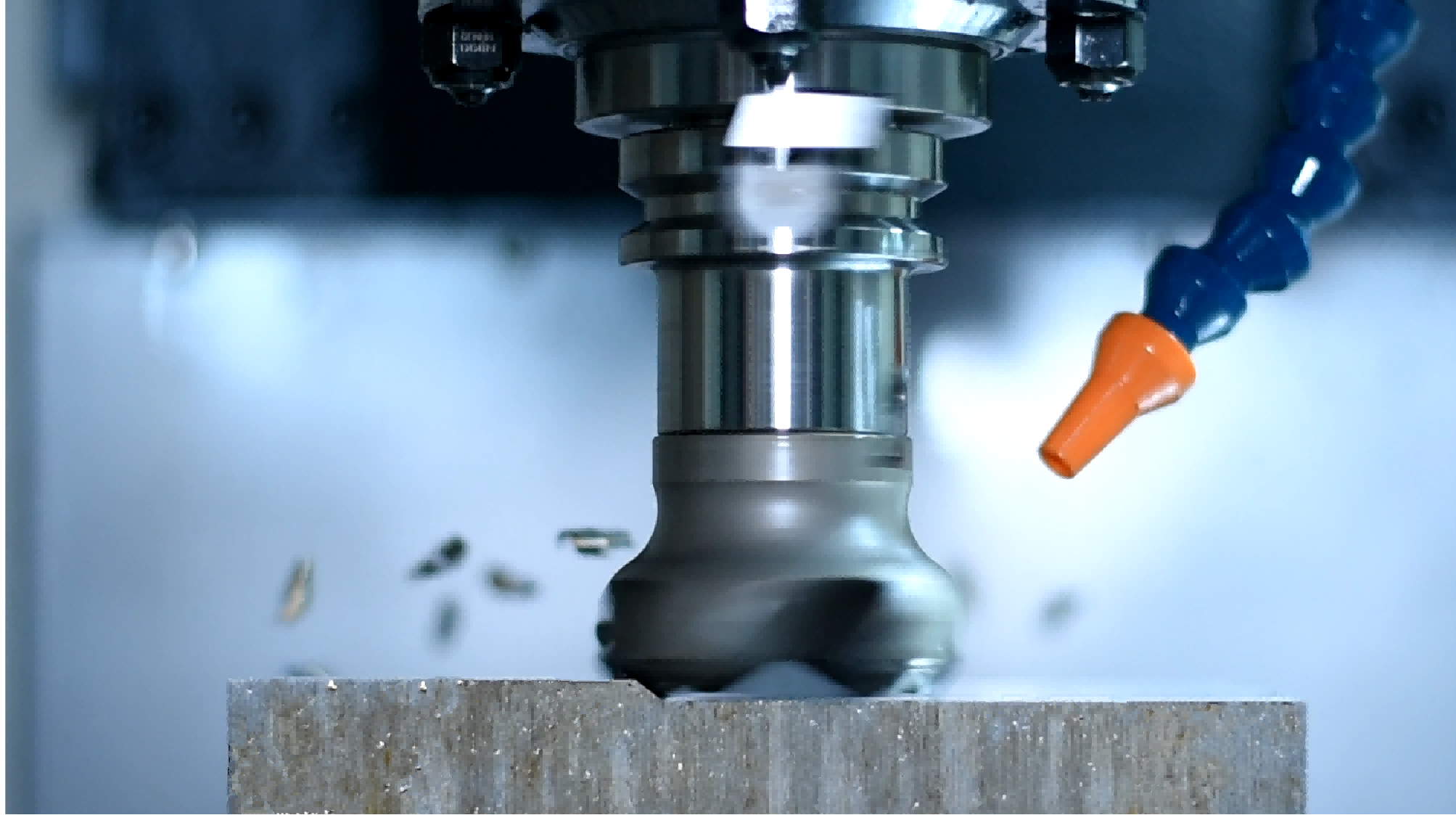

02

The spindle adopts high-rigidity and high-precision ceramic ball bearings with ultra-low

temperature rise characteristics to improve thermal elongation characteristics and cutting

precision.

03

Wide range of application, suitable for all kinds of products processing, widely used in automotive, mold , etc.

Specifications

| Item | Project | Unit | Specifications |

|---|---|---|---|

| Travel | X axis travel | mm | 1100 |

| Y axis travel | mm | 600 | |

| Z axis travel | mm | 600 | |

| Distance from spindle nose to worktable | mm | 130-730 | |

| Distance from spindle center to column | mm | 625 | |

| Workbench | Workbench size | mm | 1200x600 |

| T-slot(sizexslot no.xspace) | mm | 18x5x100 | |

| Maximum load of workbench | kg | 800 | |

| Spindle | Speed | rpm | 6000 |

| Spindle taper | # | BT50 | |

| Transfer method | # | Belt drive | |

| Feed | Three-axis cutting feed | mm/min | 1-10000 |

| Three-axis rapid feed | m/min | 36x36x36 | |

| Precision | Positioning precision | mm | 0.008/0.006/0.006 |

| Repeatability | mm | 0.005/0.004/0.004 | |

| Tool changing system | Number of tools | pcs | 24 |

| Max tool weight | kg | 18 | |

| Max tool length | mm | 300 | |

| Max tool diameter(Full tool/adjacent empty tool) | mm | 110/200 | |

| Tool magazine form | # | Disc | |

| CNC system | Control system | # | FANUC 0I-MF plus(5) (Mitsubishi M80A/M80B) |

| Spindle motor power | kw | 11/15 | |

| Three-axis motor power | kw | 3.0/3.0/3.0 | |

| Others | Required air pressure | kgf/cm3 | ≥6 |

| Electricity demand | KVA | 30 | |

| Net weight | kg | / | |

| Dimensions(LxWxH) | mm | 2900x2680x3100 |