Feature

01

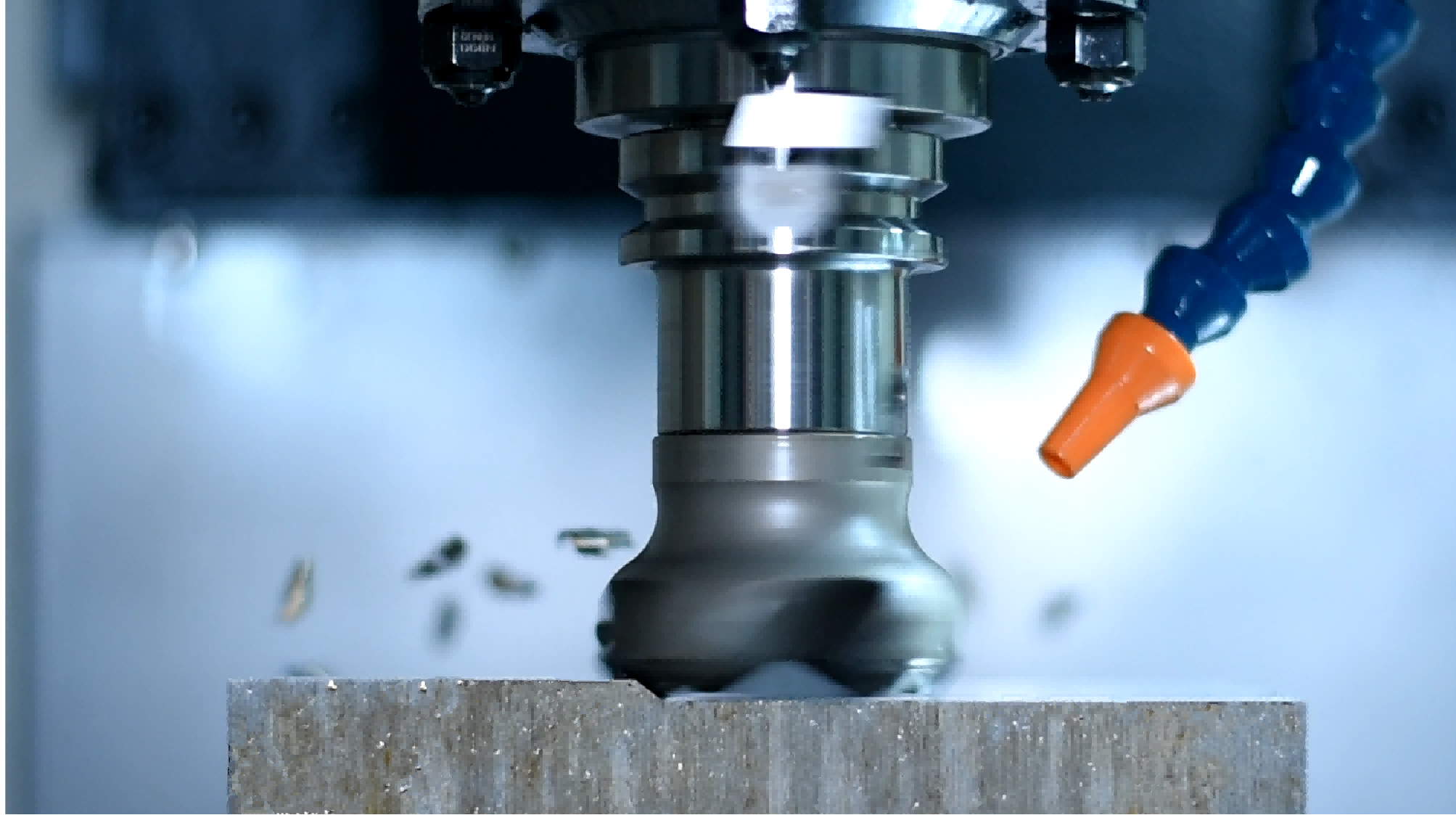

High-rigidity body design with high-rigidity extended slider which greatly improves

cutting performance

02

The shape adopts a herringbone structure design with the "golden ratio" to strengthen

the torque resistance and bending rigidity

03

The best choice for batch processing, widely used in new energy, automation hardware,

auto parts, aviation, medical and other industries

Specifications

| Item | Project | Unit | Specifications |

|---|---|---|---|

| Travel | X axis travel | mm | 820 |

| Y axis travel | mm | 550 | |

| Z axis travel | mm | 550 | |

| Distance from spindle nose to worktable | mm | 120-670 | |

| Distance from spindle center to column | mm | / | |

| Workbench | Workbench size | mm | 1000x500 |

| T-slot(sizexslot no.xspace) | mm | 18x5x80 | |

| Maximum load of workbench | kg | 600 | |

| Spindle | Speed | rpm | 10000 |

| Spindle taper | # | BT40 | |

| Transfer method | # | Belt drive | |

| Feed | Three-axis cutting feed | mm/min | 1-10000 |

| Three-axis rapid feed | m/min | 48x48x48 | |

| Precision | Positioning precision | mm | 0.008 / 0.006/0.006 |

| Repeatability | mm | 0.005 / 0.004/0.004 | |

| Tool changing system | Number of tools | pcs | 24 |

| Max tool weight | kg | 7 | |

| Max tool length | mm | 300 | |

| Max tool diameter(Full tool/adjacent empty tool) | mm | 80/150 | |

| Tool magazine form | # | Disc | |

| CNC system | Control system | # | FANUC 0I-MF |

| Spindle motor power | kw | 7.5/15 | |

| Three-axis motor power | kw | 1.8/1.8/3.0 | |

| Others | Required air pressure | kgf/cm3 | ≥6 |

| Electricity demand | KVA | 20 | |

| Net weight | kg | / | |

| Dimensions(LxWxH) | mm | 2380x2700x2800 |