Feature

01

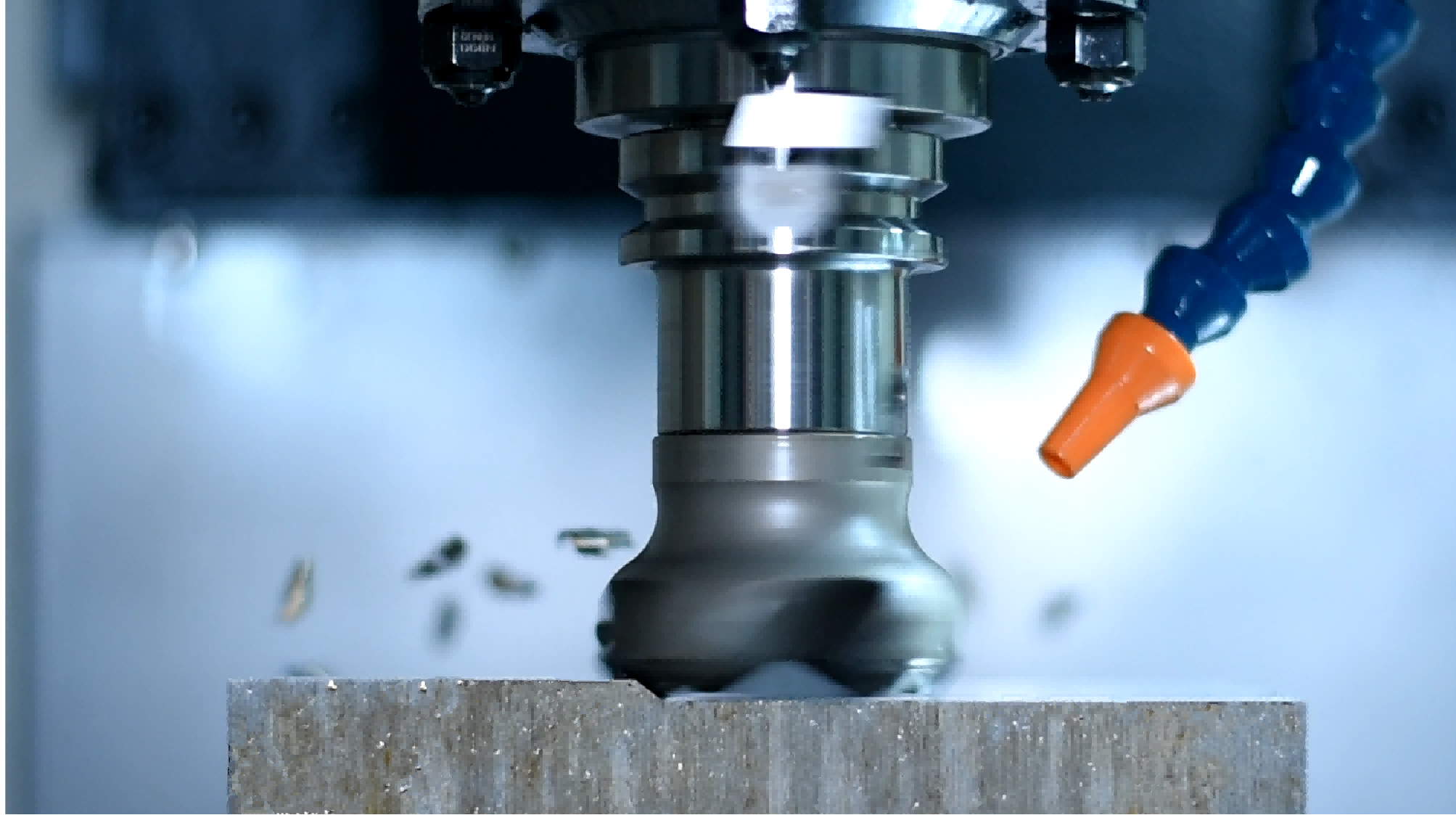

By the analysis of FEA finite elements and reniforced body structure design provides better rigidity and thermal stability.

02

It has excellent dynamic precision performance and superior processing precision during rapid displacement.

03

Cylinder counterweight on Z-axis is adopted for good stability, high safety and low driving noise, thus effectively improve the service life of screw and stability and machining presision.

Specifications

| VH-85 | Project | Unit | Specifications |

|---|---|---|---|

| Travel | X axis travel | mm | 850 |

| Y axis travel | mm | 550 | |

| Z axis travel | mm | 550 | |

| Distance from spindle nose to worktable | mm | 110-660 | |

| Distance from spindle center to column | mm | 560 | |

| Workbench | Workbench size | mm | 1000x520 |

| T-slot(sizexslot no.xspace) | mm | 18x5x80 | |

| Maximum load of workbench | kg | 600 | |

| Spindle | Speed | rpm | 10000/12000 |

| Spindle taper | # | BT40/BBT40 | |

| Transfer method | # | Belt drive/Direct drive | |

| Feed | Three-axis cutting feed | mm/min | 1-10000 |

| Three-axis rapid feed | m/min | 36x36x36 | |

| Precision | Positioning precision | mm | 0.008/0.006/0.006 |

| Repeatability | mm | 0.005/0.004/0.004 | |

| Tool changing system | Number of tools | pcs | 24 |

| Max tool weight | kg | 7 | |

| Max tool length | mm | 300 | |

| Max tool diameter(Full tool/adjacent empty tool) | mm | 80/150 | |

| Tool magazine form | # | Disc | |

| CNC system | Control system | # | FANUC 0I-MF plus(5) (Mitsubishi M80A/M80B) |

| Spindle motor power | kw | 11/18.5 | |

| Three-axis motor power | kw | 3.0/3.0/3.0 | |

| Others | Required air pressure | kgf/cm3 | ≥6 |

| Electricity demand | KVA | 25 | |

| Net weight | kg | / | |

| Dimensions(LxWxH) | mm | 2500x2750x2790 |