Feature

01

BMT55 power tool holder port

02

Reserved automatic installation interface, fast and easy to expand into an automated production line

03

Fully enclosed protection, can be equipped with 70kg high pressure water system

04

Servo programmable tailstock, standard with live top (built-in rotary sleeve is optional)

05

Spindle is equipped with encoder to realize high precision interpolation machining and high reliability angular positioning

Specifications

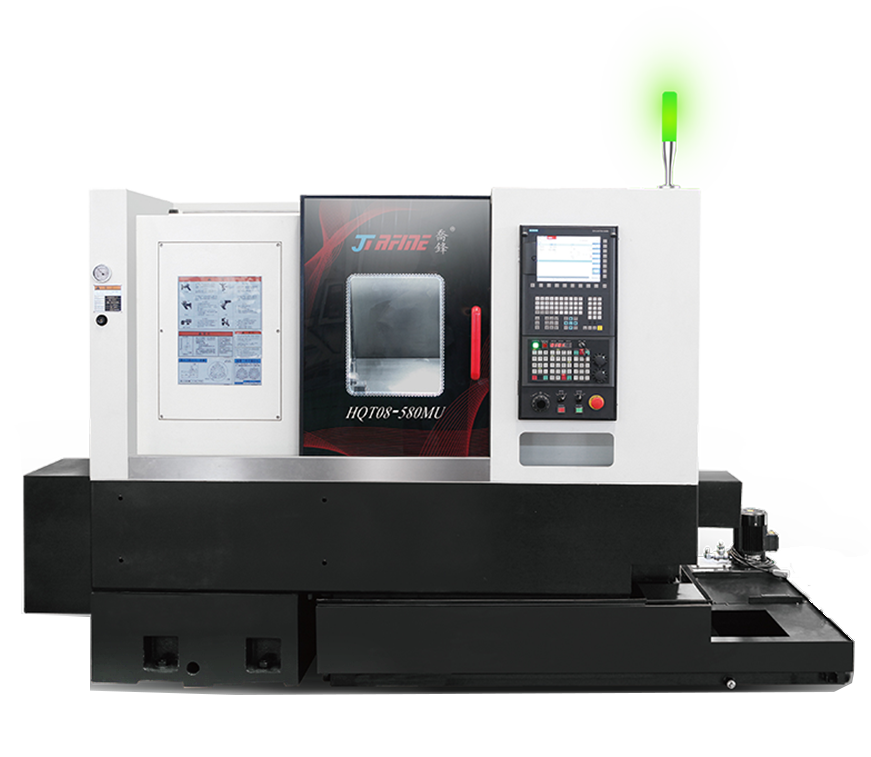

HQT08-580MU

Project

Unit

Specifications

Machining Range

Maximum Rotating Diameter

mm

Ø 580

Maximum Rotating Diameter

mm

Ø 350x390

Bore Diameter of the Spindle

mm

Ø 62

Maximum Diameter of Rod to be Machined

mm

Ø52

Maximum Supporting Weight

kg

200

Spindle

Maximum Rotating Speed of Spindle

rpm

4500

The End Type of Spindle

KAS

A2-6

The Rotation Indexing Precision of Spindle

deg

(360°)0.001

Size of Chuck

inch

8" Hollow (Solid) Chuck

Travel

Travel Length of Axis-X

mm

225

Travel Length of Axis-Z

mm

450

Feed

Fast Moving Speed of Axis X

m/min

30

Fast Moving Speed of Axis Z

m/min

36

Precision

Repeated Positioning Accuracy

mm

0.005(Full Travel Length)

Repeated Positioning

mm

0.002 (Full Travel)

Turret

Total Number of Tools

pcs

12

Tool Changing Time

sec

0.2

Height of Outer Arbor

mm

25x25

Maximum Diameter of Inner Arbor

mm

Ø 40

Maximum speed of milling spindle

r/min

5000

Milling spindle motor power

KW

6.2[S3-40%]

The tailstock

Tailstock Form

#

Programmable Servo

Maximum Movement of Tailstock

mm

540

Taper Hole Form of Tailstock

#

MT4

The motor

Control System

#

Siemens 828D

SpindleMotor

KW

17.2

Axial Servo Motor X/Z

KW

2.2/2.2

Water Tank Capacity

L

120

Power Demands

KVA

30

Net Weight

kg

#

Overall Dimension(Length × Width × Height)

mm

3735x1862.5x1815